Floating dry docks

Why Floating Dry Docks Are an Important Part of Shipbuilding

Introduction

A floating dry dock is a type of shipbuilding facility that allows ships to be built and launched in a controlled environment. These docks are typically used for large, complex vessels that require special attention during construction.

While floating dry docks have been around for centuries, they continue to play an important role in modern shipbuilding. In this post, we'll explore the history of these docks, how they work, and the different types that are used today. We'll also discuss the advantages of using a floating dry dock over traditional methods of shipbuilding.

What is a Floating Dry Dock

How Does a Floating Dry Dock Work

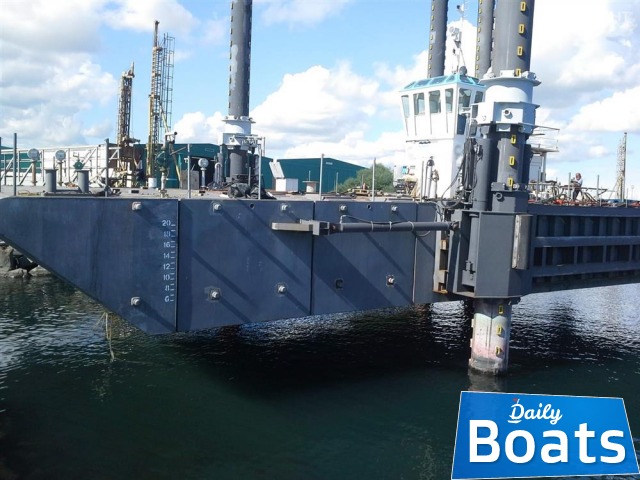

A floating dry dock is a type of pontoon that can be used to support and repair ships. The dock is flooded with water, which allows it to float, and then the ship is floated into position on top of the dock. Once the ship is in place, the water is pumped out of the dock, leaving the ship suspended in air. This allows workers to access the bottom of the ship for repairs.

There are two main types of floating dry docks: keel blocks and caisson docks. Keel blocks are typically used for smaller ships, while caisson docks can accommodate larger vessels. Caisson docks are also more commonly used in shipyards, as they can be easily moved around and positioned as needed.

Floating dry docks have a long history, dating back to ancient Rome where they were first used to repair ships. In more recent years, they have become an essential part of shipbuilding and repairing, as they provide a safe and efficient way to access the bottom of a ship for repairs.

The History of Floating Dry Docks

The Benefits of Floating Dry Docks

Floating dry docks have been used for centuries to repair and build ships. The first recorded use of a floating dry dock was in 1495, when the Venetian Navy used one to repair a damaged warship. Since then, floating dry docks have been used extensively in shipbuilding and ship repair.

There are many benefits to using floating dry docks. They allow ships to be built and repaired in any water depth, which is essential for large vessels that cannot be easily moved. Floating dry docks also provide a stable environment for work, as the dock itself moves with the waves rather than the ship. This reduces the risk of damage to both the ship and its crew.

There are two main types of floating dry docks: internal and external. Internal floating dry docks are enclosed on all sides, while external floating dry docks have an open side that allows access to the hull of the ship being worked on. External floating dry docks are more common, as they are less expensive to build and maintain.

The future of floating dry docks looks bright, as they continue to be an essential part of shipbuilding and ship repair around the world.

The Different Types of Floating Dry Docks

The Future of Floating Dry Docks

A floating dry dock is a type of shipbuilding facility that allows ships to be built in a dry environment. The first floating dry dock was invented in the early 1800s, and since then, they have become an essential part of shipbuilding. There are three main types of floating dry docks: gantry, cantilever, and pontoon.

Gantry docks are the most common type of floating dry dock. They consist of a platform that is supported by two or more piers. The platform can be raised or lowered using hydraulic jacks. Gantry docks are typically used for smaller vessels such as yachts and barges.

Cantilever docks are similar to gantry docks, but they only have one pier. Cantilever docks are typically used for larger vessels such as cruise ships and oil tankers.

Pontoon docks are the largest type of floating dry dock. They consist of a series of connected pontoons that support a large platform. Pontoon docks are typically used for very large vessels such as container ships and aircraft carriers.

The future of floating dry docks is bright. With the continued growth of the shipping industry, there is a need for more shipbuilding facilities. Floating dry docks offer a safe and efficient way to build ships, and they will continue to be an important part of the shipbuilding process for years to come.

Conclusion

A floating dry dock is a structure that allows a ship to be floated into place for construction or repair. These docks are an important part of shipbuilding because they provide a safe and efficient way to build and repair ships.

The history of floating dry docks dates back to the 18th century, when they were first used in England. Since then, they have been used all over the world and have become an essential part of shipbuilding. The benefits of floating dry docks include their flexibility, safety, and efficiency.

There are different types of floating dry docks, each with its own advantages. The future of floating dry docks looks bright, as new technologies are being developed that will make them even more efficient and effective.